HydroStor End Cap Installation

HydroStor Endcaps are available with a prefabricated stub for ready connections to the inlet pipe. However, field fabrication of endcaps may be desired in certain situations for connecting a pipe stub to an inlet/outlet manifold. This can be done by hand using a reciprocating saw and does not require welding the stub to the endcap. With proper installation procedure, field fabricated stubs will perform similarly to prefabricated, welded stubs. The video, steps and document below show the requirements for a field fabricated stub connection.

Field Cut Video Guide

Quick Start Guide

Cut

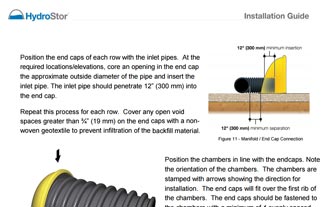

First, find the appropriate scribe line for the diameter and invert elevation of pipe you will be using. If needed, mark the line with a marker for better visibility while cutting. Then, using a reciprocating saw, carefully cut along the guide. The difference between the outside diameter of the pipe and the hole must be less than ½” (13 mm).

Insert Pipe

Insert the pipe stub a minimum of 12” (300 mm) into the endcap. Any voids greater than ¾” (19 mm) should be covered with a non-woven geotextile to keep the crushed rock from infiltrating the connection.