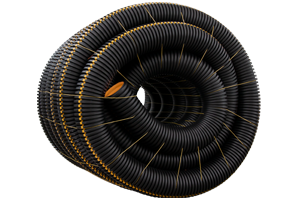

GOLDFLEX®

Flexible Dual-Wall

Product Type: Dual-Wall

Goldflex® flexible dual-wall pipe has revolutionized the installation of agricultural drainage mains. It feeds directly from a stringer to a plow boot for a trenchless installation that vastly increases speed and improves safety.

As pioneers of flexible dual-wall, Prinsco continues to push the industry forward by leading the creation of a first-ever ASTM standard for flexible dual-wall pipe.

Our Goldflex gold standard of quality has now become ASTM F3390.

Contact your Prinsco sales rep to learn more about GOLDFLEX®.

Related

Goldflex® Benefits

- Meets ASTM F3390

- Fast installs – 60% faster than dual-wall sticks

- Dual-wall – offers optimum flow rates

- Trenchless – increases safety

- Less labor & equipment

- Ideal for high water table areas

- Easier handling – less curling off the stringer

- Easier coupling – less force needed to join ends

- Increased structural performance – more confidence

| Diameter (in.) | Perforation | Nominal Length |

|---|---|---|

| 8″ | None | 825′ |

| 8″ | Perforated | 825′ |

| 8″ | Perforated w. Sock | 825′ |

| 8″ | Narrow Slot | 825′ |

| 12″ | None | 320′ |

| 12″ | Perforated | 320′ |

| 12″ | Perforated w. Sock | 320′ |

| 12″ | Narrow Slot | 320′ |

| 15″ | None | 190′ |

| 15″ | Perforated | 190′ |

| 15″ | Perforated w. Sock | 190′ |

| 15″ | Narrow Slot | 190′ |

- ASTM F 3390: Standard Specification for 3″ – 24″ (75mm – 600mm) Lined Flexible Corrugated Polyethylene Pipe for Land Drainage Applications

Product Brochures

Specifications

Installation Guides

CAD Drawings

Catalogs

Technical Notes

Most factory boots designed to install large diameter single wall pipe can be used to install Goldflex of the same diameter. A minimum 50-inch bend radius is recommended to minimize the forces on the pipe as it moves through the boot. More specific boot dimensions are referenced in Prinsco’s Goldflex Installation Guide.